16 cylinders. Displacement of 8 liters. 1,001 PS. When Bugatti published the first technical details about the engine for the Veyron 16.4 in 2005, it instantly changed the game. It was sensational. Never before had a production vehicle featured an engine which was so powerful, yet so compact and able to cruise as easily as it could obliterate acceleration records. Its power output was unparalleled at the time; acceleration from 0 to 100 km/h in just 2.5 seconds and a top speed of over 400 km/h. When the Veyron 16.4 went into production, it marked a pioneering achievement for Bugatti, and established an entirely new class of car in the process – the Veyron was the world’s first hyper sports car. And it wouldn’t have been possible without the W16.

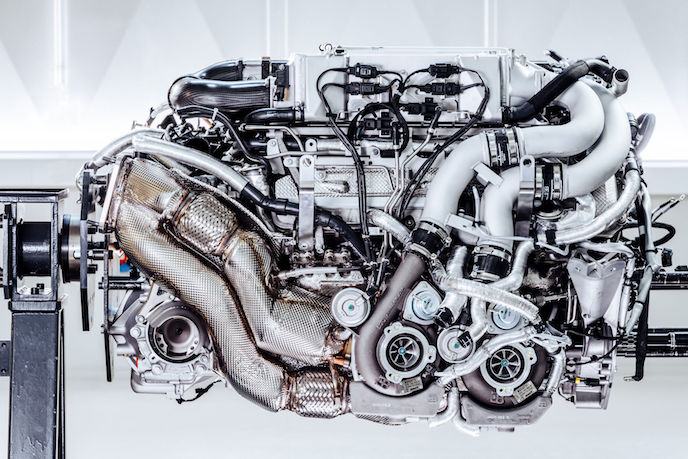

Bugatti unveiled its successor, the Chiron, in March 2016. And once again achieved the unexpected. What was once thought to be an unachievable amount of power in a road car, in Veyron, was surpassed by around 50 percent in Chiron. Yes, it was an 8.0-liter W16, and yes it had four turbochargers – just like Veyron – but achieving new levels of performance meant looking at every single component afresh. Most importantly, larger turbochargers and a duplex fuel injection system with 32 injection valves was fitted, with a greater use of carbon and titanium to help offset increases in weight. With its power output of 1,500 PS initially, subsequently increased to 1,600 PS, and maximum torque of 1,600 Nm, the W16 engine changed the course of performance car history yet again.

The Genesis of the W16 engine

Its development was a lengthy process. In 1997, standout engineer Ferdinand Karl Piëch, Chairman of the Board of Management of Volkswagen AG at the time, presented VW’s Head of Engine Development Karl-Heinz Neumann with the initial idea, drawing it on an envelope while traveling on the Shinkansen high-speed train from Tokyo to Osaka. His idea was an engine with 18 cylinders, but it would subsequently be modified to become the W16 we know today. A fitting homage to the 16-cylinder engine developed by Ettore Bugatti himself.

Gregor Gries, who was one of the first Bugatti employees during its rebirth 20 years ago and, until February 2022, was the company’s Head of Technical Development, reminisces: “At the time, no one really believed there could be a vehicle for the road that boasted 1,000 PS. We wanted to prove we could construct an engine that was not only powerful, but also manageable.” The engineers started from scratch. “We had to engage in basic development for every component; every vehicle part had to be constructed anew and tested – even the engine test bench. The only thing we didn’t change was the pencils we used for drawing,” says Gregor Gries, laughing. “We felt like Ettore Bugatti back in the day – he too always developed his own tools.”

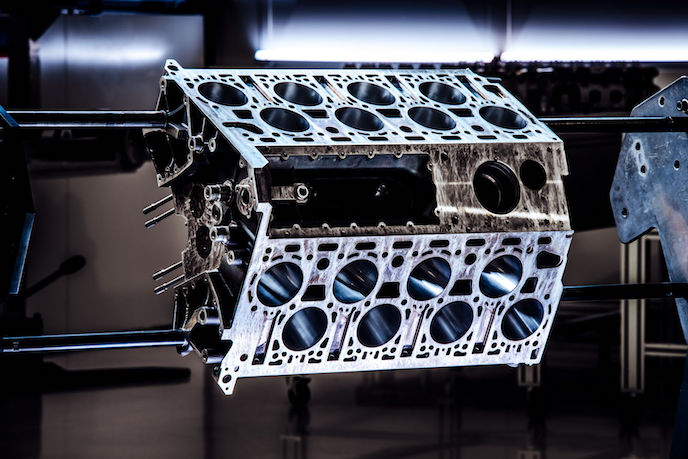

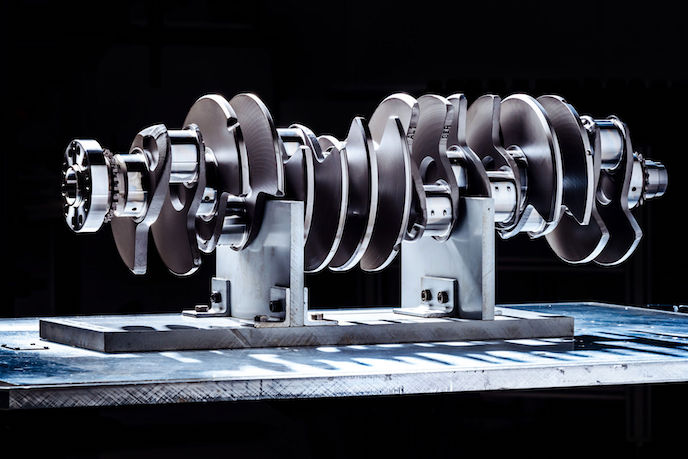

The engineers took Ferdinand Piëch’s idea sketched on an envelope and evolved it into a production reality. No bigger than a V12, and weighing around 400kg, the engine has the unique arrangement of cylinders in a ‘W’ configuration to thank for its compact size. Two eight-cylinder blocks are set at an angle of 90 degrees to one another, boosted by four exhaust gas turbochargers. But the challenges that Karl-Heinz Neumann and his team faced to transform the W16 into a reality were immense.

“Back then, there was no literature or empirical data for production engines with more than twelve cylinders or for production vehicles that could go faster than 350 km/h,” relates Neumann. “One thing proved to be a particular headache – the car had to stay grounded, its power had to stay on the road – which isn’t easy at these speeds. But proving it was possible to construct an engine that could deliver this was incredibly cool. There was a real sense of fulfillment when the W16 was finally up and running.”

Development of the W16 engine

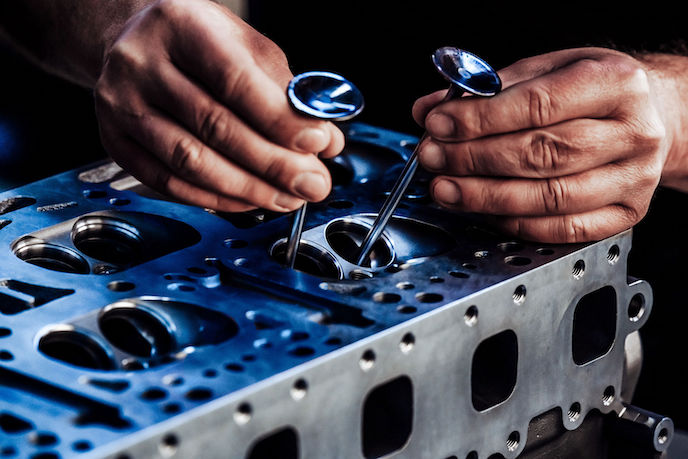

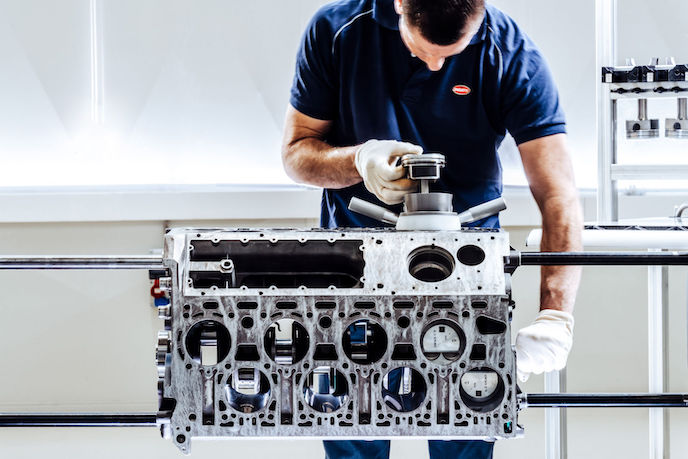

Bringing the engine to life required more than 3,500 individual parts, each assembled by hand, and the work monitored throughout by test computers. On its first ever test in 2001, the double biturbo engine achieved the required 1,000+1 PS right off the bat – the theory and the execution could not have been better. But such were the leaps in performance that traditional engine test bench and ventilation systems could not cope with the new W16 – new systems had to be specially developed. There were also new requirements not previously asked of a production vehicle, such as the fact the very hot exhaust gas needed to be channeled. A titanium exhaust system on a scale not previously seen in the automotive sector was ultimately part of the solution.

With performance secured, the engineers turned their attention to smoothness and reliability. As a 16-cylinder set up offers naturally smooth running, detecting a misfire or knocking in the engine by traditional methods would be unreliable. Bugatti therefore developed Bugatti Ion Current Sensing (BIS) to monitor the ion current flowing at each spark plug. If the system detects knocking combustion or a misfire, the ignition timing is slowed, the cylinder deactivated, or the boost pressure reduced. Every single cylinder can run right at its limit of performance. “From the outset, our aim was to generate maximum engine performance in a stable, clean manner,” explains Gregor Gries, former Head of Development at Bugatti, who has been responsible for engine and transmission development since Bugatti’s rebirth.

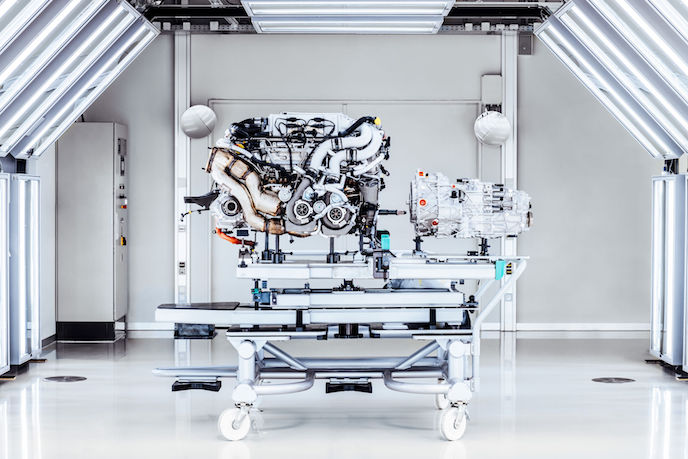

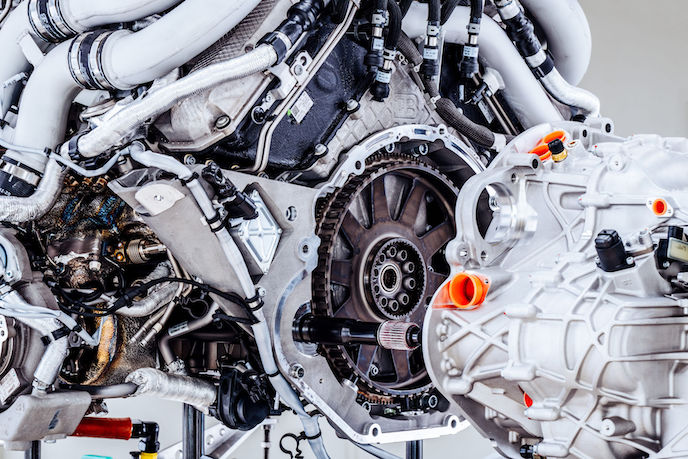

Absolutely crucial to the continued reliability of the W16 engine was its cooling system and – as you would expect – it was engineered on a scale never before seen in the automotive industry. A complex water-cooling system, featuring two water cycles, keeps the W16 within the required temperature range, even at extreme full loads. 40 liters of water flows through the high-temperature cycle with three coolers in the front end to keep the engine at its operating temperature. The low-temperature cycle with a separate water pump contains 15 liters of cooling water to bring the turbochargers’ heated charge air down by as much as 130 degrees in two heat exchangers on the engine. There are also coolers each for the differential oil, transmission oil, and engine oil, as well as a heat exchanger for the air conditioning system. The W16 is incorporated into the Veyron as a longitudinally mounted mid-engine with seven-speed dual-clutch transmission located in front of the engine.

Turbochargers are usually added to boost the power of small engines. In the case of BugattiI, the basic motor already boasts sufficient power output, but the four turbochargers build on these strong foundations to create something truly incomparable. “Being on the road with the W16 means having a limitless feeling of power and performance, of infinite performance. Whatever the speed, the engine has sufficient reserves for additional acceleration in any situation. When a quick switch is made from cruising to fast driving, the W16 remains smooth and commanding, and never feels strained. This unique boundlessness is what our customers find so beguiling,” relates Pierre-Henri Raphanel, Bugatti’s Pilote Officiel, who has driven Veyron and Chiron for well over 100,000 km.

“With the engine of the Veyron 16.4, Bugatti showed even before mass production that only an exceptional team could realize this engine concept. Only with the immeasurable commitment of the employees could this standout engine be improved, redesigned, and perfected again and again over the years,” says Bugatti Automobiles President, Christophe Piochon, who still raves about everyone’s untiring will to not give up. This unique engine encapsulates the Ettore Bugatti credo: “If comparable, it is no longer Bugatti.”

The sound of the engine is as unique as the engine itself. Thanks to an entirely stand-alone, asymmetric firing order with firing gaps of just 45 degrees, its sound is unlike any other engine concept. Balanced and comfortable in the lower load range, it increasingly becomes a growling beast as the load increases. And all without mechanical noise interference.

The engineers continued to optimize the engine over the years. With enlarged turbochargers and many other modifications, the W16 delivered 1,200 PS in the Veyron 16.4 Super Sport from 2010. That same year, the Super Sport set a speed record of 431.072 km/h as the fastest road-legal production super sports car, thereby earning itself an entry into the legendary Guinness Book of Records.

Further development for the Chiron

The Veyron 16.4 and its derivatives Grand Sport, Super Sport and Grand Sport Vitesse have become prized collector’s pieces. Bugatti is already thinking about a new successor model while production of one vehicle is in full swing. The brand and the product have transformed the landscape of performance cars– unrelentingly fast, elegant, reliable, luxurious, and exclusive.

With the Chiron, the engineers faced the challenge of developing a similarly sophisticated but even more luxurious and more powerful successor model. They wanted to make the W16 more powerful, quieter, and more cultivated, and therefore once again pushed the boundaries of what’s technically feasible. “As well as greater power output based on the same dimensions and engine weight, we wanted to improve the acoustics, consumption, and emissions,” remembers Tilo Fürstenberg, one-time Head of Engine Development at Bugatti.

The only aspects the engineers kept were the compact engine shape and the pitch of 73 millimeters – everything else was developed anew. The result was a new, quiet, efficient, and powerful engine with 1,500 PS – with more direct responsiveness and power delivery the likes of which had never been seen before. This equates to a 50 percent increase in power over the original basic engine development of the Veyron 16.4 and an approximately 24 percent increase over the Veyron 16.4 Super Sport.

Introduction of sequential turbocharging

Much of the engine’s new performance comes from the exhaust gas turbochargers with special, new sequential turbocharging. The increase in output to initially 1,500 PS and, for the Chiron Super Sport and the Centodieci, an additional 100 PS to 1,600 PS, calls for four exhaust gas turbochargers. Each charger must provide sufficient air flow for approximately 380 PS. This is made possible thanks to two-stage turbocharging (sequential turbocharging) where two turbochargers come into play one after the other. These are 69 percent larger than those of the Veyron.

Only when all four turbochargers – two on each bank of cylinders – are in use does the engine achieve its maximum power output. In the Chiron, the exhaust gas turbocharger that runs permanently and the exhaust gas turbocharger that can be deactivated are the same size – ideal for a steady torque path without any noticeable slumps. The exhaust gas valve that forms a part of this operation has to be able to able to withstand temperatures of 980 degrees Celsius while remaining fully mobile – Bugatti therefore uses a special high-temperature material alloy for the main components.

The development work paid off, with the Chiron Super Sport 300+ breaking a speed record in 2019 to become the first production automobile to surpass the 300-mph mark. Hitting a speed of exactly 304.773 mph (490.484 km/h), the Chiron Super Sport 300+ is the fastest production sports car around. At the same time, Bugatti increased the electronic limiter to a previously unapproved speed of 440 km/h (273 mph), making the Chiron Super Sport the fastest production BugattiI of all time and the Centodieci an especially powerful limited-edition few-off. And all of this was derived from a brilliant idea for a unique engine.

Christophe Piochon said: “Who would have thought we would continue to develop the W16 for so long and so impressively? Starting at 1,001 PS, we added 200 PS with the Veyron Super Sport and Vitesse. We then made a huge leap to 1,500 PS with the Chiron in 2016 and added a further 100 PS in the Chiron Super Sport and Centodieci between then and 2019. In other words, we increased the W16’s power output by 60 percent in the space of 14 years. On top of this, there is the variability when accelerating, the fantastic longitudinal acceleration of the Chiron Super Sport, and the unique lateral acceleration of the Chiron Pur Sport. Each of our four basic Chiron models – the Chiron, Chiron Sport, Chiron Pur Sport and Chiron Super Sport – has its very own driving style. Not to mention the coach-built models Divo, Centodieci and La Voiture Noire, as well as the Bolide still to be built. In all honesty, the longer I think about it, the more impressed I am by the W16 engine.”

16,000 hours of testing and six days of manual work

Bugatti tested the 16-cylinder engine prior to production with the aid of computer simulations and on a newly developed engine test bench. The Chiron engine ran for over 16,000 hours during development. In addition, more than 500,000 test kilometers were completed in the vehicle in order for the engine to live up to Bugatti’s demanding quality standards. The engine is manufactured at the Volkswagen engine plant in Salzgitter – in a separate room reserved exclusively for building the W16 engine. It takes two experts six days to meticulously manually assemble the engine’s 3,712 individual parts. The finished engine is then carefully packed and transported to Molsheim, where the engine and transmission are put together as the first step in the Chiron’s final assembly at the Bugatti Atelier. This is followed by weeks of manual work until another unique hyper sports car is stood on all four wheels, ready for delivery.